There is a powerful new industrial tool in the College of Engineering, a revolutionary machine that combines precise machining with advanced 3D printing to repair and rebuild large metal parts.

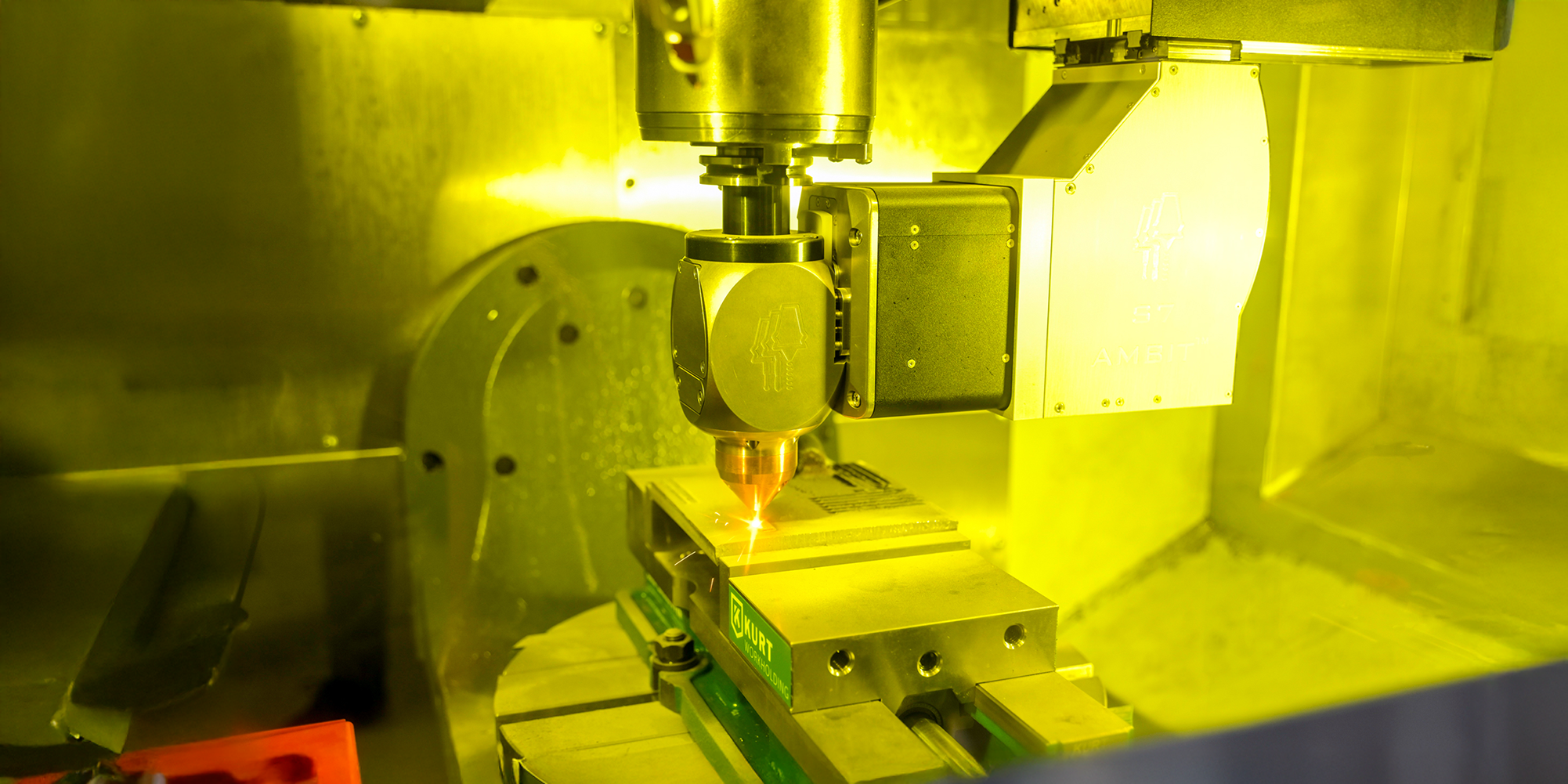

Tucked in a Mechanical and Aerospace Engineering building at the University of Florida, this 3D printing technology — Direct Energy Deposition (DED) — has been integrated into an existing computer numerically controlled (CNC) machine. The hybrid technology opens new possibilities in sustainable manufacturing and interdisciplinary research.

The system could transform how industries repair and remanufacture everything from airplane parts to bridge components. It is part of ISE’s additive manufacturing expansion and is intentionally placed in a shared space to encourage collaboration across departments in the college.

“The whole idea of this system is to do repairs,” said Iris Rivero, department chair of Industrial & Systems Engineering at the University of Florida. “For example, airplane engines, agricultural equipment and other very large components don’t have to be scrapped. We can repair them with minimal amount of materials and put them back into service.”

Funded by the Department of Energy, the testing prototype uses both additive and subtractive manufacturing techniques with raw materials like powder or wire. The project explores the system’s ability to fuse new material directly onto damaged, cracked or worn surfaces in a process known as directed energy deposition. Installed on campus in mid-July, the machine cost nearly $400,000.

The equipment’s capabilities allow both additive and subtractive operations to be performed in a single setup, making it possible for industries to encourage their customers to use remanufactured components. For example, remanufactured engine blocks can be used for agricultural equipment or in infrastructure to repair bridges.

Here’s how it works: When a tractor engine cracks and the original design or material details are unavailable; the AMBIT tool can print material directly into the damaged area. This means there is no need to discard the entire engine. The repair process starts with the machine’s subtractive capabilities creating pockets where cracks have formed, then performs (DED) with the AMBIT head to fill those pockets by fusing powder or wire metals onto the existing surface.

Rivero highlighted two major advantages. First, it significantly reduces CO2 emissions making it more environmentally friendly. Second, because it’s rare for 3D printers to use wire metals, the AMBIT tool opens exciting new avenues for research, especially with expensive metals.

“A lot of companies will have a high interest in this technology,” Rivero said.

That interest is already sparking research. UF ISE Ph.D. candidate Andrea Camacho-Betancourt is putting the machine to work.

“The cost and materials savings of remanufacturing when compared to completely remaking a part are drastic, especially when coupled with our research to ensure the remanufactured parts meet structural integrity needs,” said Camacho-Betancourt.

Current student projects use traditional metal powder that matches the metal of the repair surface to evaluate how well the metals fuse together. They’re also investigating how different powders fuse with substrate metals, focusing on remanufacturing integrity. One study involves repairing low alloy steel with Inconel 625 powder, a nickel-based superalloy.

The team analyzes how the deposited material interacts with the substrate, how well the materials have diluted together, stress formation and hardness. The data informs future deposition parameters to optimize for stronger repairs.

Research with the hybrid system is driving innovation toward more cost-effective manufacturing repairs with potential to transform how industries approach maintenance and sustainability.